Kind of amazing that I haven’t already done something like this – sliced it open on the inside of the body structure while trying to thread a coarse nut onto a fine-threaded tap bolt. Duh.

Kind of amazing that I haven’t already done something like this – sliced it open on the inside of the body structure while trying to thread a coarse nut onto a fine-threaded tap bolt. Duh.

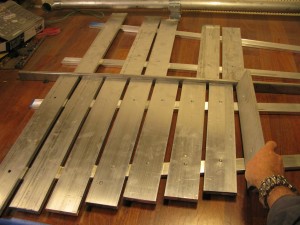

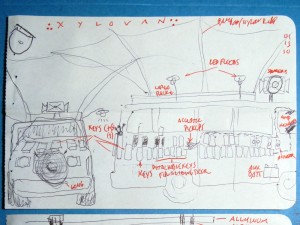

Today we began sorting out the foundational hardware – the junk that holds the xylophones to the van. They’re going to be big, look heavy, visit this site and somewhat springy, and we don’t want them flexing loose or tearing the metal.

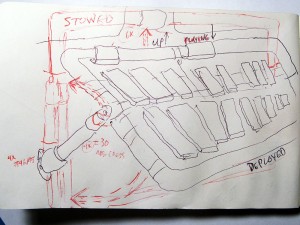

Rogan helped me hem and haw my way through the engineering challenge – how can we make the keyboards ride high enough when stowed that they won’t scrape the ground – but still be easy to deploy and play? … Continue reading First blood, first panel surgery