By now you’ve probably gathered I’m not an engineer. None of the XyloVan team is, price really.

By now you’ve probably gathered I’m not an engineer. None of the XyloVan team is, price really.

As a result, patient this build blog is more a chaotic pile of raw coverage than a fetishistically neat, information pills step-by-step how-to.

This rolling concert instrument (I do dream of a fleet of instrumental art cars – DrumVan, or PianoBoat, anyone?) is taking shape in a raw, organic form in our minds .

I’m not computing engineering challenges ahead of time. I’m figgerin’ ’em out as soon as I get my hands on the materials.

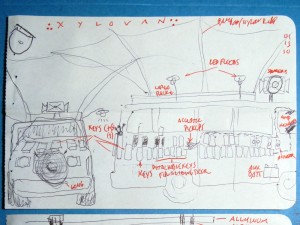

This means I use sketches as a sort of problem-solving tool rather than a full-on architectural spec.

So this one (above) is one of the earliest, showing a three-quarter view and all the gross components we’re planning to build and attach – xylophones, gongs, lights, sun-shelters, speakers, etc.

I’m posting these largely because tonight’s the deadline for Maker Faire entries and we’re hoping to have the van in some kind of playable shape by then.

So on the one hand, you have crudely-detailed sketches like these:

And on the other hand … Continue reading The Big Picture is all in your head